Our Integrated Computational and Materials Engineering (ICME) approach bridges the gap between material science and finite element analysis making digital twin technology a reality

AlphaSTAR’s ICME Approach

Integrated Computational Materials Engineering

Multi-scale

Progressive Failure

Analysis

In modern engineering, revolutionary products are dependent on revolutionary material systems.. Whether pursuing hypersonic applications, deep ocean energy extraction, or extremely sensitive medical devices, understanding materials, predicting material behavior, and establishing material databases are the foundation for successful product development.

Material

Characterization &

Qualification

In the realm of Additive Manufacturing, our software tools allow builders to apply predictive analytics in ways that avoid common 3D printing defects, while analyzing the phase change and microstructural change that takes place during the production process — from powder to finished parts.

Build Simulation

for Additive

Manufacturing

We not only predict anomalies but also the effects of those defects on the final product. Digital Twin technology based on fundamental material science is in our DNA.

Our Integrated Computational and Materials Engineering (ICME) approach bridges the gap between material science and finite element analysis making digital twin technology a reality

Over three decades of supporting the nation’s Warfighters

Bringing our micromechanics digital twin technology for polymer 3D Printing build simulation to Siemens customers worldwide

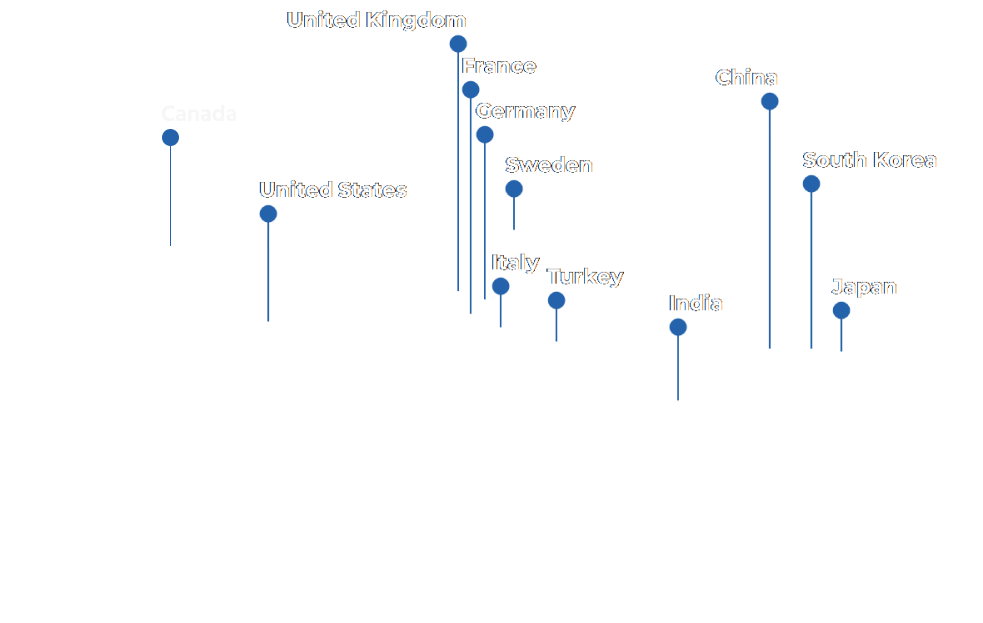

We have deployed our technology in over 20 Countries Worldwide with Partner Channels in APAC, EMEA, and North America

Now available as a plug-in to GrabCAD Print Pro™

Grounded in Advanced Material Science That’s Made Simple and Accessible

True Physics-Based Analytical Solution for High-Resolution and Computationally-Efficiency

Verified, Validated and Implemented

Based on 30+ Years of Advanced Research Addressing Mission-Critical Challenges

Comprehensive Simulation Toolset for Advanced Material Modeling, Advanced Manufacturing, Virtual Testing and AM Process Optimization

AlphaSTAR’s ICME Approach

Integrated Computational Materials Engineering

In modern engineering, revolutionary products are dependent on revolutionary material systems. Whether pursuing hypersonic applications, deep ocean energy extraction, or extremely sensitive medical devices, understanding materials, predicting material behavior, and establishing material databases are the foundation for successful product development.

We not only predict anomalies but also the effects of those defects on the final product. Digital Twin technology based on fundamental material science is in our DNA.

In the realm of Additive Manufacturing, our software tools allow builders to apply predictive analytics in ways that avoid common 3D printing defects, while analyzing the phase change and microstructural change that takes place during the production process — from powder to finished parts.

AlphaSTAR’s ICME Approach

Integrated Computational Materials Engineering

In modern engineering, revolutionary products are dependent on revolutionary material systems. Whether pursuing hypersonic applications, deep ocean energy extraction, or extremely sensitive medical devices, understanding materials, predicting material behavior, and establishing material databases are the foundation for successful product development.

We not only predict anomalies but also the effects of those defects on the final product. Digital Twin technology based on fundamental material science is in our DNA.

We not only predict anomalies but also the effects of those defects on the final product. Digital Twin technology based on fundamental material science is in our DNA.

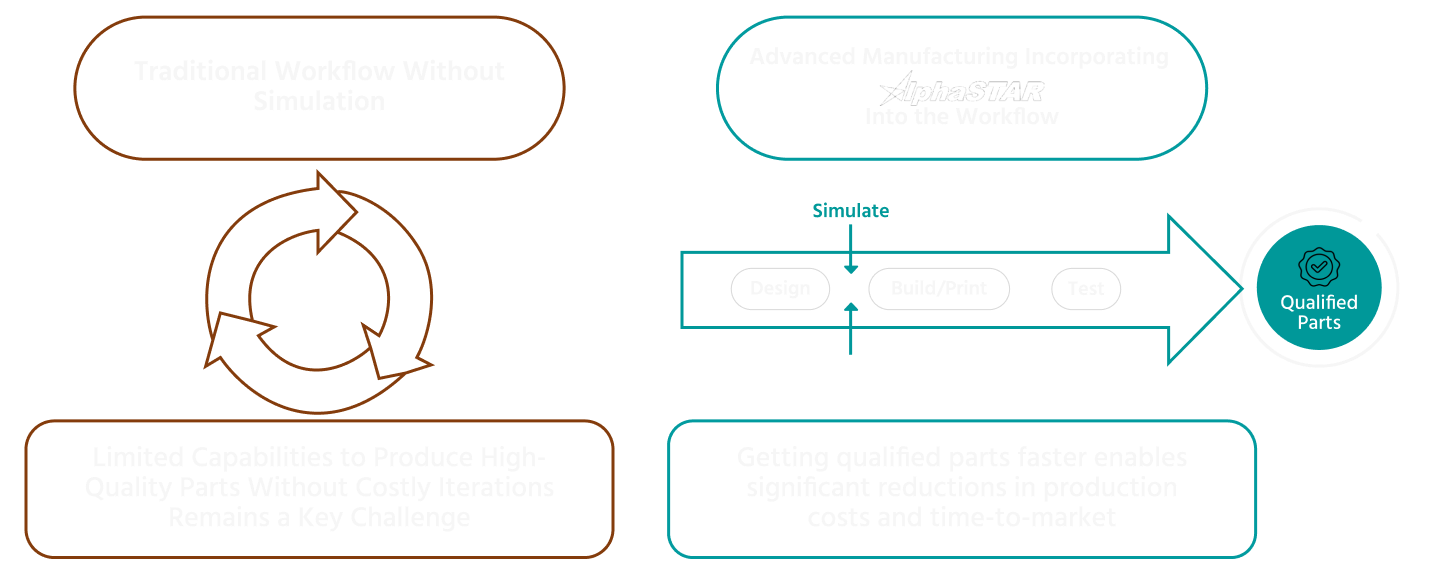

Additive Manufacturing Simulation –

Powered by AlphaSTAR’s Thermo-Mechanical

AM Part Qualification

Reducing Trial & Error of Conventional

Manufacturing Processes

AlphaSTAR tools provide a digital blueprint or “digital twin” of the part

being built before production even starts

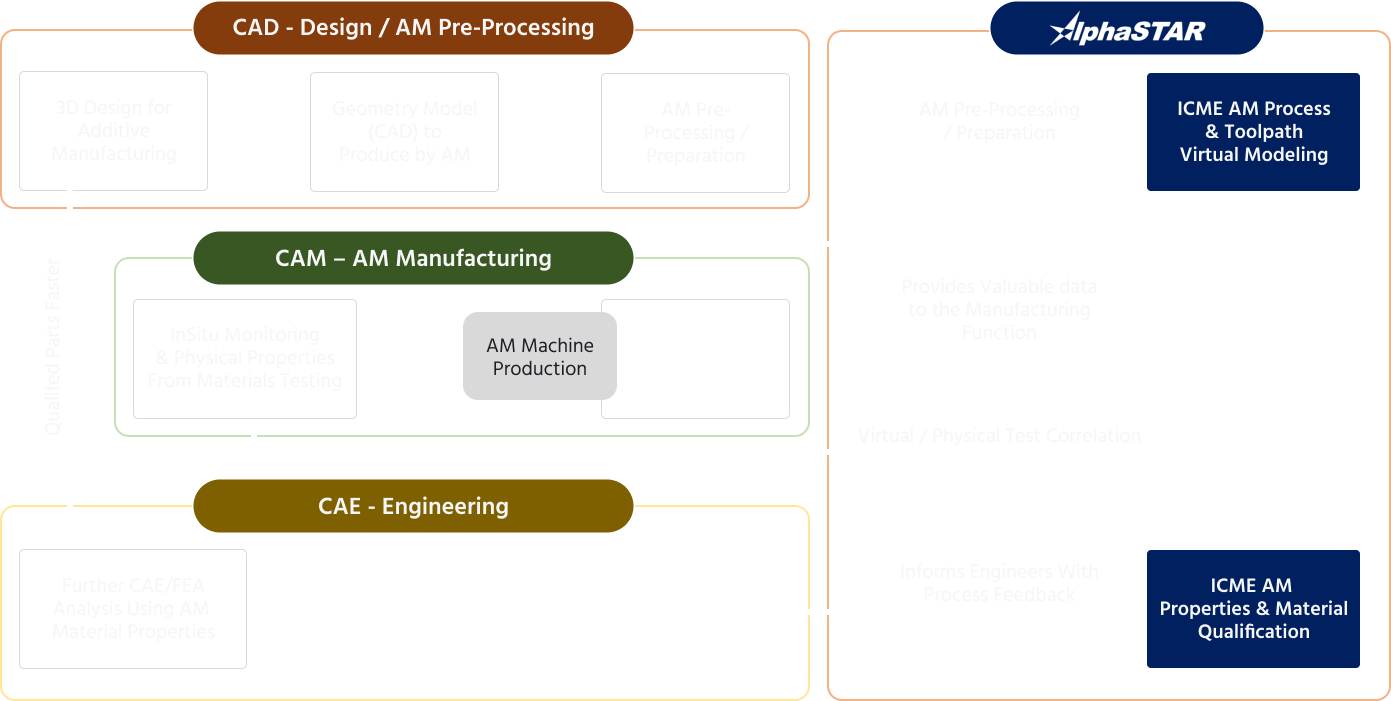

Where  Fits Into

Fits Into

Conventional AM Workflows

Highly-Adaptable Simulation Technology to

Address a Variety of Use Cases in Traditional

Advanced and Additive Manufacturing

Stand-alone Tools

Embedded Into Build Prep Software

Extensions to Traditional FEA Packages

Tools for Engineering Departments

Down To Shop Floor Practitioners

Applicable to Macro-sized Parts Down to Nano-level Material Particles

FE Partners

Applications

While its legacy has been in serving the US Department of Defense, NASA, multiple federal agencies and leading US defense

contractors in mission-critical applications, today AlphaSTAR works with product designers, product developers, and manufacturers

from all walks of life to address a multitude of applications and functional challenges with broad market potential.

AlphaSTAR Solutions

Augments traditional FE solvers to predict behavior of advanced composite materials and structures subject to various loading conditions (static, fatigue, impact, environmental

Combination of an as-built de-homogenized material model and multi-scale progressive failure analysis

Integrates damage initiation, material degradation and fracture evolution

Track damage initiation and propagation until final failure

Trusted by Blue Chip Institutions Across the Advanced Manufacturing Ecosystem

2601 Main Street #660 Irvine, CA 92614

(562) 961 - 7827

info@alphastarcorp.com

@2022 - 2023 AlphaSTAR. All rights reserved. Trademarks used herein are trademark or registered tradmarks of AlphaSTAR. All other names and brands are registered trademarks of their respective companies.